In the modern world of manufacturing the need for high-precision components, sustainable production techniques and cost-effective methods has driven a quiet but powerful revolution: industrial powder metalurgical. Powder metallurgy has a distinct distinction from traditional metalworking that involves cutting, forging or casting. Instead metal powders are melted and pressed into high-performance complex components. This method is not just efficient, but it opens up innovative design possibilities that were previously challenging or impossible to accomplish with conventional machine tools.

Powder metallurgy has been a crucial component for a range of industries that span from aerospace and automotive to electronics, energy, and medical technology. The ability to create precise, sturdy and virtually-net-shaped pieces helps manufacturers cut down on waste and increase consistency in their products. The technique is particularly well-suited to high-volume, high-speed manufacturing environments where efficiency and precision must not be compromised.

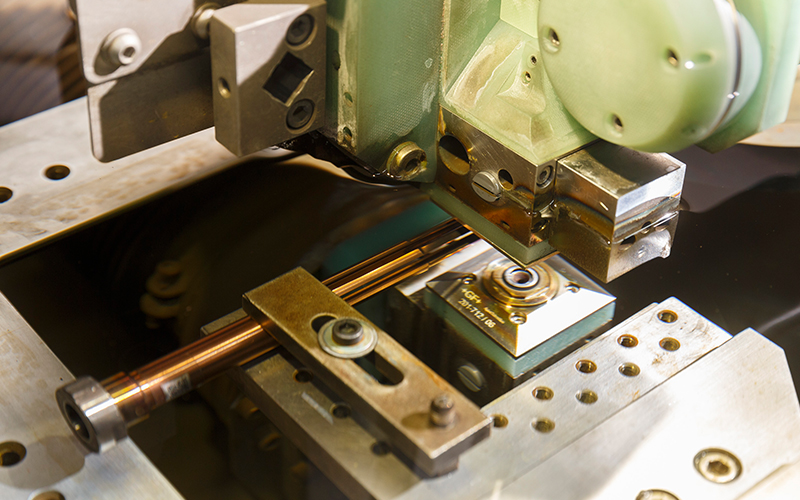

Image credit: tw.porite.com

Porite Taiwan: Leading the Way in Powder Metallurgy

Of the world’s leaders in this field, Porite Taiwan stands out as a significant force. As a core member of the Porite Group, Porite Taiwan is responsible for almost 50% of the group’s production. As one of the world’s most famous powder metallurgy firms in the field, Porite Taiwan has years of expertise in engineering, cutting-edge technology, and a rigorous quality control to every product. The components are used in a myriad of products, such as motor vehicles, household appliances aviation systems and electrical instruments.

The success of the manufacturing process at Porite is based on its capacity to satisfy complex, large-scale demands, and to ensure that every component meets the highest international standards. The company’s knowledge of metallurgy, sintering and other technologies allows it to create solutions that are tailored for particular industry needs. The company’s reputation is built on the foundation of reliability and accuracy which are vital qualities in today’s global competitive market.

Metal Injection Molding and Precision Manufacturing

Metal injection molding is a variation of powder metallurgy. Metal injection (MIM) is like plastic molding mixes fine metallic powders and binder to create an able moldable material. The binder is removed, and the part is then was sprayed to ensure durability and strength.

This process permits the development of highly intricate metal components with tight tolerances as well as superior mechanical properties. MIM’s ability to produce small, detailed parts in huge quantities makes it an ideal choice for industries like medical devices, consumer products, electronics and defense. The ability to combine intricate geometry with high-performance materials is what makes MIM an efficient tool in modern product development. Top metal injection molders are focusing more and more on innovation in order to meet the ever-changing demands of their clients.

Sintered metal filters: A quiet but essential component

Sintered metal filters are among of the most important, yet overlooked applications of powdered metallics. These filters use the same pressing and silting techniques, but they are designed so that impurities can be filtered and gases or liquids are able to flow through. A trusted sintered metal filters manufacturer must ensure that each filter performs under high pressure, extreme temperatures, or corrosive environments without compromising integrity or efficiency.

In industries like pharmaceuticals as well as food processing, petrochemicals as well as clean energy, sintered metal filters are widely used. They are renowned for their reliable filtration capabilities and long-lasting performance. They also require minimal maintenance.

Powder Metallurgy is a Future-Ready Manufacturing Solution

Powder metallurgy companies play an essential role in the growth of the global manufacturing sector. Powder metallurgy is an excellent option for industries that are experiencing rising costs, stricter regulations, and increased competition.

The entire powder metallurgy ecosystem is driving innovation, redefining the manufacturing of metal. From high-tech injection molding firms to reputable makers of sintered metal filters, this industry is transforming the metal manufacturing industry. Porite Taiwan, a leader in the field sets benchmarks for global standards. The future of precision metal parts are being made and sintered every day.